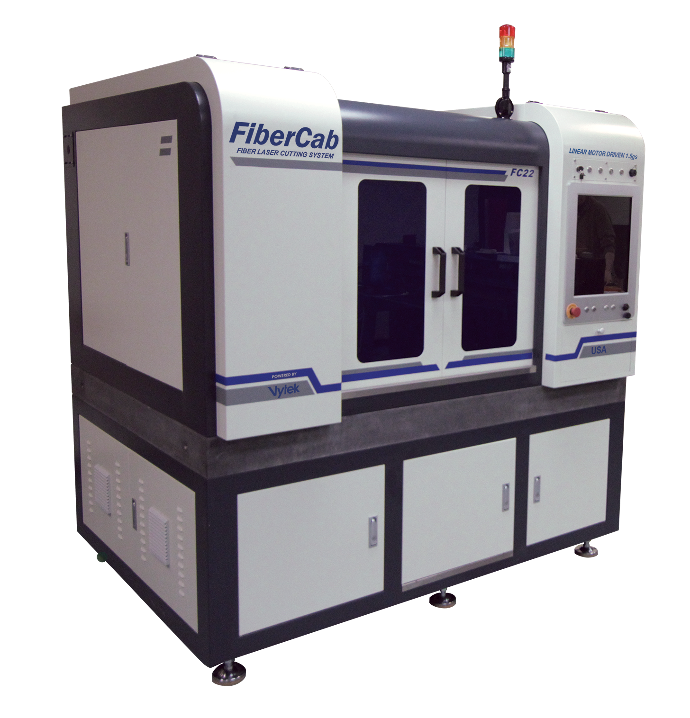

FCL22

Laser Cutting System

The FiberCab Mini FCL22 Laser Cutting Platform from Vytek is a game-changing solution for small to micro part processing. With over 25 years of experience in building production laser and CNC equipment, the Mini-series is a true advancement in laser cutting platform design.

Designed and optimized for both ferrous and non-ferrous metals, the FCL22 boasts the ability to process materials as thin as .0002" / .005mm. With the capability to resolve part geometries to as small as .0005"/.012mm, the FiberCab Mini FCL22 ensures unmatched precision and accuracy.

The FCL22 incorporates ALL ironless linear motors mounted to a thermally stable GRANITE base, resulting in an extremely high acceleration drive system while maintaining the most demanding of accuracies. With the latest generation of controls and a user-friendly interface, the FiberCab Mini FCL22 is among the highest throughput systems on the market, regardless of size.

Experience the power of the FiberCab Mini FCL22 Laser Cutting Platform for yourself and take advantage of our limited-time promotional offer. Don't miss out on the opportunity to revolutionize your small to micro part processing with unmatched precision and speed.

FEATURES

Pneumatic Clamps

Our Modular Adjustable Table design, unique in the industry, incorporates a pneumatic hold down clamping system and eliminates the need for the support slats while securely holding the smallest materials in place. The table system is fully adjustable for material widths as small as 2”/50mm and eliminates contact on the back side of the material and the damage caused by supports. This revolutionary approach to material support also allows for multiple work zones with the addition of up to 3 pairs of clamp sets.

Control Interface

The FCL series is built around a rugged integrated machine interface which features a full graphic display and allows total machine and program control right at the machine console. The operator has full control of all critical job-related parameters, allowing on the fly job edits while monitoring machine performance. Complete job statistics as well as remote support from Vytek are all standard.

Drop Through Table

The FCL series table system also features a drop through well design that also doubles as the fume/dust extraction plenum. Access to material drops is easy with a convenient front door access and a fully removable drawer for easy unloading.

Laser Source

The FCL series can be equipped with a variety of laser sources in both single and multi-mode configurations in both air and water-cooled formats. The FCL22 platform is available with up to 3kW in CW laser sources. Focused spot sizes can range from as small as 10um (with single-mode fibers) and as large as 200um. We also offer specialty laser sources in other wavelengths including Pico and Femto second in custom configurations.

Cutting Head

The Cutting Head and its optical configuration are an important part of the laser system, so we carefully match the cutting head configuration to the applications to ensure peak performance. We offer a wide variety of configurations to best match the laser choice and spot size requirements and offer head options in both manual and auto focusing, to meet any production requirement.

Linear Motors

The linear motor drives are iron-free to keep it running smooth and steady for years to come and the user interface offers many control options to help bring your project to life.

MACHINE SPECIFICATIONS*

LASER TYPE (Wavelength)

Fiber: 1000, 1500, 3000, Watt Pulsed Fiber (1.070nm)

WEIGHT

4500 lbs (approx)

POWER CONSUMPTION W/O LASER*

≤450W

MAX PART SIZE n (mm)

24″ x 24″ (610 mm x 610mm)

Maximum Part Height mm (in)

51mm (2")

OUTSIDE DIMENSIONS, mm (in), HxWxL

812 x 558 x 660 (64” x 79” x 84”)

*Specifications are subject to change without notice.

FCL SERIES LASER SYSTEMS IN ACTION

MACHINE OPTIONS

Dust Extraction Options

1.5kW Dust and Fume Extraction Unit

- Exchanges inside air using Pre filters and HEPA filtration

Requires Filter Replacement based on Frequency of Use

UPGRADE 3kW 2 filter Self Contained Dust Extraction Unit (Recommended)

- Exchanges inside air using 2 filter cannisters

- Requires Filter Replacement based on Frequency of Use

- Operates at 400v 3ph and requires compressed air

NOTE: For Medium Duty use up to 6 hours/day of cutting

Other Options

Gas Regulator for Medium Pressure Oxygen

- Medium pressure gas regulator for use with gas or liquid assist gas

Gas Regulator for High Pressure Nitrogen

- High pressure gas regulator for use with gas or liquid assist gas

Step Up Transformer: 220v to 400v for 3kW to 6kW Lasers

- Fiber laser sources require the operating voltage to be 400 volts

Step Down Transformer: 480v to 400v for 3kW to 6kW Lasers

- Fiber laser sources require the operating voltage to be 400 volts

I-Laser Vision PLUS Alignment System

- For alignment of printed metal sheet with registration marks

- Head mounted high resolution camera with lighting

WANT MORE INFORMATION ON THE FCL SERIES?

NOT SURE WHICH PRODUCT IS RIGHT FOR YOU?

Simply answer a few questions about your industry or the materials you work with, and our program will design a machine that will meet your specific production or manufacturing needs.