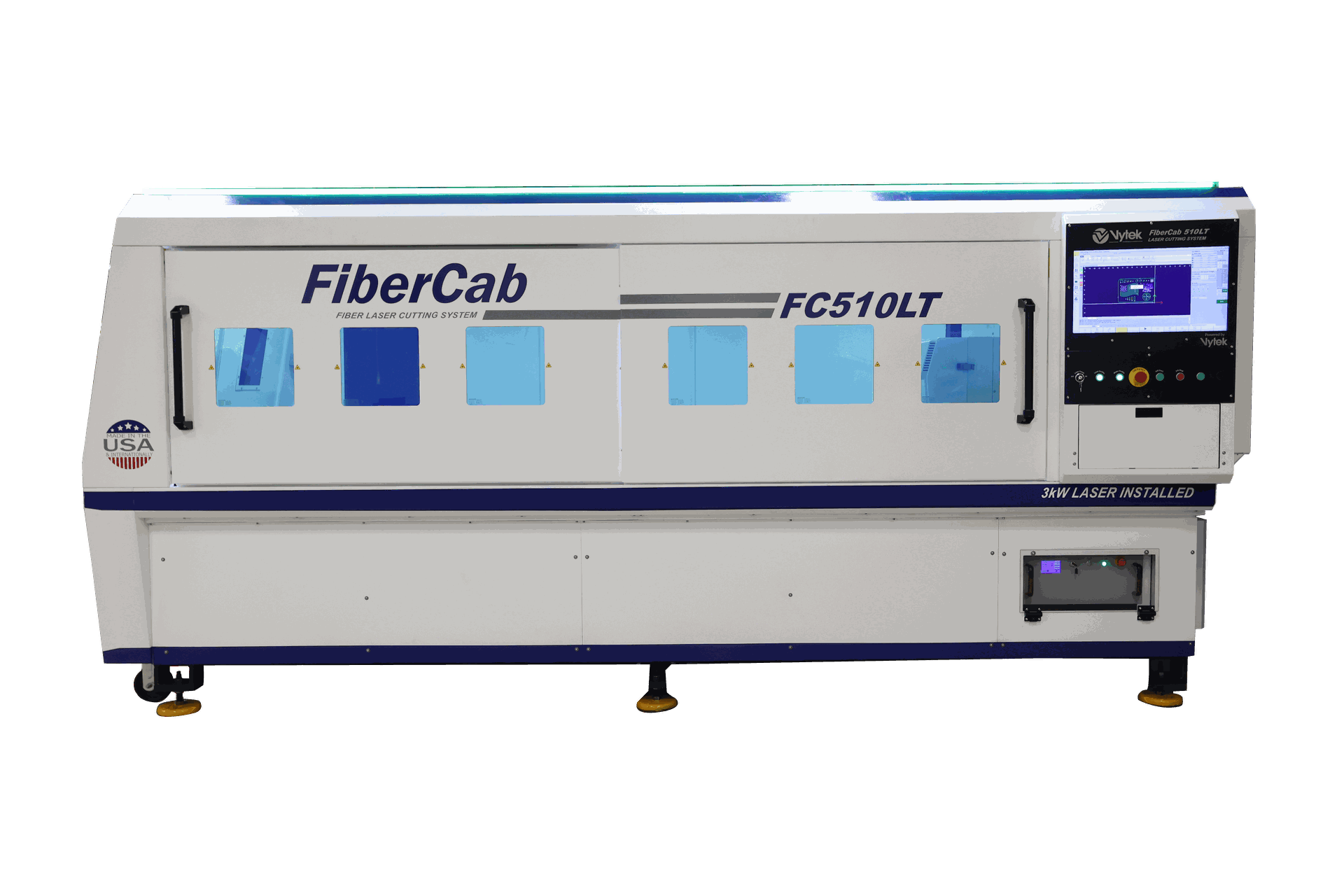

The FiberCAB LT Series is the newest model in the FiberCab family. It is built upon over 30 years of experience building laser and CNC equipment.

The FC510LT model was designed to meet the needs of real Fabricators and Manufacturers. It offers a full 5’ x 10’ sheet capability in a small package at an affordable price. The FC510LT can be equipped with laser powers from 1kW to 6kW for cutting from gauge sheet metal to over 1/2” plate capacity (laser power dependent). It utilizes high performance brushless AC servo drives and our latest controls and software.

The LT series boasts easy access to the full cutting surface while maintaining a small footprint when the system is not in use. Along with its other standard features, the FC510LT offers upgradable options and configurations.

REQUEST QUOTE

FEATURES

Cutting Heads

The FC510LT Series can be configured to use a range of cutting heads to suit the user needs. Users can easily interchange focus heads to the ideal configuration for the job at hand.

High-Precision Servo Drives

The FC510LT line uses an advanced, all brushless servo motor drives that are directly connected to the main motion board for faster servo update rates and seamless motion at high speeds.

Integrated Table

The integrated table allows for easy access to the entire cutting surface while maintaining the smallest possible footprint by not using additional floor space when the table is retracted.

Control Interface

The FC510LT series is an entirely new generation control designed to make laser cutting easier while allowing at the machine programing directly from the control. The control platform supports:

- Multiple import filters DXF, AI and more

- Preset material libraries and processes

- Multiple pierce types

- Corner looping

- Work offsets

- Optional nesting

- And so much more….

MACHINE SPECIFICATIONS

LASER TYPE (Wavelength)

The FC510LT is available in CW water cooled from 1000 watts through 4000 watts and can achieve highly focused spot density resulting in cutting speeds up to *4 times that of comparable CO2 laser.

POWER CONSUMPTION W/O LASER*

≤450W

WEIGHT

18,000 lbs (approx)

OUTSIDE DIMENSIONS, mm (in), HxWxL

4343 x 2286 x 2057 (171″ x 90″ x 81″)

Max Part Size mm (in) W x L

1524 x 3048 (60″ x 120″)

Maximum Part Height mm (in)

102 mm (4")

FC510LT SYSTEM IN ACTION

MACHINE AVAILABLE OPTIONS

Table Options

Automatic Dual Shuttle

- Automatically changes tables between jobs

- Allows load/unload while other table is processing

- Includes two table pallets

- Integrated safety guards

- Material hold down clamps

Special Options

I-Laser Vision Plus Alignment System

- For auto alignment of sheet and pre cut parts

- Head mounted high resolution camera with lighting

Gas Regulator for Medium Pressure Oxygen

- Medium pressure gas regulator for use with gas or liquid assist gas

Gas Regulator for High Pressure Nitrogen

- High pressure gas regulator for use with gas or liquid assist gas

Step Up Transfer (3kW - 6kW Lasers)

- 220v to 400v as fiber laser power sources require an operating voltage of 400v

Step Down Transformer (3kW - 6kW Lasers)

- 480v to 400v as fiber laser power sources require an operating voltage of 400v

Dust Extraction Options

1.5kW 3 Stage Self Contained Extraction Unit

- Exchanges inside air using Pre filters and HEPA filtration

- Requires filter replacement based on frequency of use

- Operates at 110v

NOTE: For Light Duty use up to 2 hours/day of cutting

3kW 2 Filter Self Contained Dust Extraction Unit

- Exchanges inside air using 2 filter cannisters

- Requires Filter Replacement based on Frequency of Use

- Operates at 400v 3ph

NOTE: For Medium Duty use up to 4 hours/day of cutting

5.5kW 4 Filter Self Contained Dust Extraction Unit

- Exchanges inside air using 4 filter cannisters

- Requires Filter Replacement based on Frequency of Use

- Operates at 400v 3ph

NOTE: For Heavy Duty use for 8 hours/day + of cutting

WANT MORE INFORMATION ON THE FC510LT?

NOT SURE WHICH PRODUCT IS RIGHT FOR YOU?

Simply answer a few questions about your industry or the materials you work with, and our program will design a machine that will meet your specific production or manufacturing needs.